Our Services

01254 384777

What We Do

Mauris blandit aliquet elit, eget tincidunt nibh pulvinar a. Vestibulum ante ipsum prim Mauris blandit aliquet elit, eget tincidunt nibh.

Polishing

A surface enhancement through metal removal, generally using abrasive belts and wheels.

Buffing

A mechanical technique used after polishing to generate a smooth finished surface, free of lines and other surface defects.

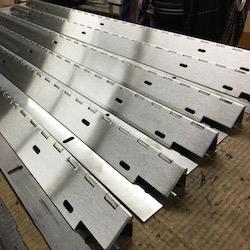

Mass Finishing (Vibratory/Tumble Finishing)

Processing parts in a container to remove burrs or scale or to improve the surface—using abrasive or non-abrasive media, water and compound—before other treatments such as plating or painting.

O.D. Tube-Polishing

Stainless steel tubular parts, are installed in high-visibility areas, so the tube’s OD needs to exhibit a smooth, blemish-free appearance

Bead Blasting

The process of removing surface deposits by applying fine glass beads at a high pressure without damaging the surface. This provides a consistent finish.

Industries we provide our services

Residential

Pharmaceutical & Health

Industrial

Aerospace

Automotive

Sculpture

Polishing

A surface enhancement through metal removal,generally using abrasive belts and wheels.

- Stroke Sanding

- Hand Polishing

- Food Grade Polishing

- Grinding and Blending

- RA Specific Finishes

- #3 – #6 Finish

Buffing

A mechanical technique used after polishing to generate a smooth finished surface, free of lines and other surface defects.

- #7 Finish (Mirror finish with grain lines)

- #8 Finish (Mirror finish w/o grain lines)

Mass Finishing (Vibratory/Tumble Finishing)

Processing parts in a container to remove burrs or scale or to improve the surface—using abrasive or non-abrasive media, water and compound—before other treatments such as plating or painting.

- Vibratory Deburring

- Vibratory Polishing (Keramo Polishing)

- Descaling

- Degreasing

O.D. Tube-Polishing

- 4″ OD x 20’ L Max size

- #3 Finish to #6 Finish

- Straight

- Bent

- Squared

- Oval

Bead Blasting

The process of removing surface deposits by applying fine glass beads at a high pressure without damaging the surface. This provides a consistent finish.

- Our blast is a 60/40 mix of #8 glass bead and aluminum oxide

- We can blast parts as big as 32” x 24” and 30 pounds

Get Started

Please contact us with any questions or comments using the information below. We look forward to hearing from you. Thank you!